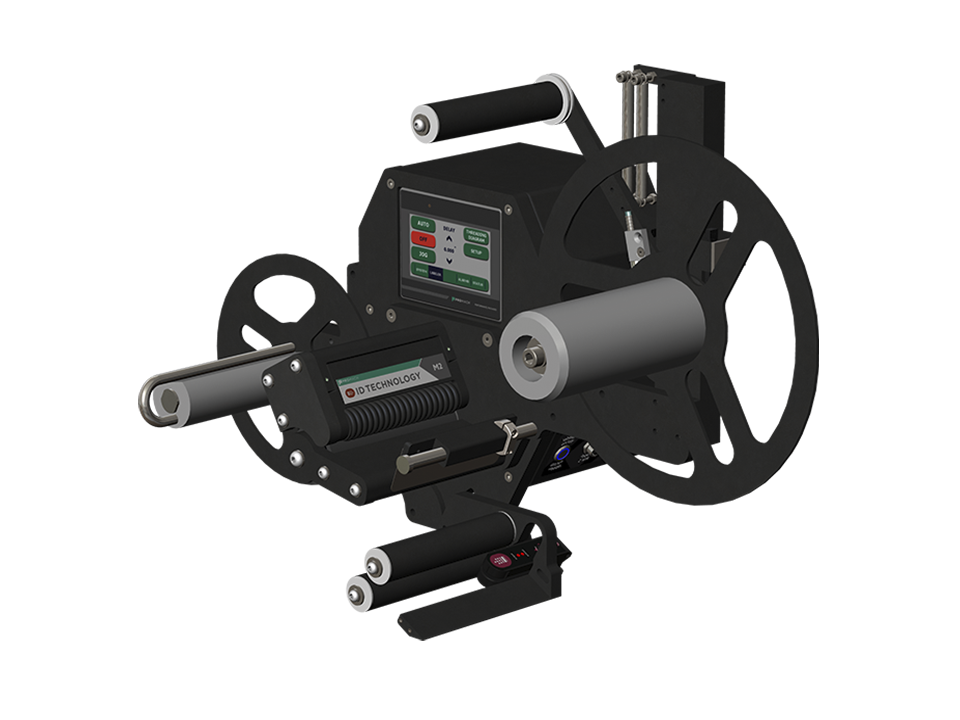

The M2 is a compact label applicator designed to be simple to integrate into many packaging systems.

Engineered as a modular concept, the M2 incorporates the operator HMI, the label feed components, and all the controls into an elegant IP65-rated package.

The M2 has accurate speed following (when using an encoder) and a higher speed capability allowing it to address faster and more demanding applications.

For high-volume packaging lines, a pair of M2 applicators can be set up as a zero-downtime pair - avoiding the need to stop production for label roll replenishment.

Product Overview:

SIMPLICITY

Setting up and operating the M2 Label Applicator is simple and easy.

- Intuitive Operation - can be set up in minutes.

- Easy to integrate alarms, label sensors and more.

- Touch screen offers improved visibility with more control.

- 100 recipes with USB back-up, restore, and cloning options.

SERVICEABILITY

The M2 Label Applicator features a modular design for maximum serviceability.

- All new controls completely onboard and protected.

- Module-based service in a matter of minutes.

- Fully connectorized inside and out.

- Quick drive roller change.

FLEXIBILITY

Regardless of your application or production environment, the M2 integrates seamlessly into existing production lines.

- It can be mounted in any orientation - top, bottom or side label application.

- Quick adjustments for maximum uptime.

- Onboard help for ease of use with alarms and flags for troubleshooting.

DURABILITY

The M2 Label Applicator is versatile, durable, and designed for easy setup and operation.

- Aluminum cabinet, so the heat is quickly dissipated.

- New nip roller lever with high visibility and ease of operation.

- Ball bearing rollers for longer life and less tension on the system.

- Standard IP65 certified as standard.

Solutions for:

Senior Leadership

Your Challenges:

- You need to add labeling capability to your packaging operations but are concerned that adding new equipment might take up too much space.

- One of your concerns is improving productivity, so any equipment purchased needs to meet this.

- Your operations team reports that existing legacy labelers are costly to maintain and repair, reducing margins.

Our Solutions:

- EPI’s compact M2 label applicator is engineered to work with your existing line layout without needing additional space.

- Based on EPI's intelligent Titanium motion control, the M2 is a low-maintenance label applicator with minimal moving parts. It is designed to operate with minimal downtime. For maximum productivity, it is available in a dual zero-down version to eliminate downtime for label roll replenishment.

- The simplicity of the modular M2 design ensures that it needs very little attention from your maintenance or operator teams, keeping operating costs to a minimum and improving efficiency.

Operations Management

Your Challenges:

- You are under pressure to reduce the cost of repairs and parts.

- Your goals include improving the efficiency of the packaging lines.

- Having to stop production for label roll changes impacts your overall OEE.

Our Solutions:

- The modular design of the M2 system minimizes the number of parts that need to be stocked, and simple engineering ensures fast and cost-effective repairs.

- The simple HMI interface of the M2 helps your operators get up to speed quickly, and the recipe feature ensures fast product changeovers.

- The zero-downtime (ZDT) version of M2 allows it to operate without stoppages for label replenishment, avoiding any reduction in your line OEE.

Operators & Technicians

Your Challenges:

- Many packaging machines are complicated and time-consuming to set up, causing frustrations for everyone on the packaging line.

- The cost of maintenance and repairs can be a challenge in many cases.

- It is often difficult to get quality training for new packaging equipment.

Our Solutions:

- The UII is so simple to use and maintain that you’ll only have to interact with it to replenish labels – leaving you with plenty of time to take care of other tasks on the packaging line.

- The M2 is built to IP65 specifications as standard - ensuring the equipment is robust enough for any situation. The modular design makes routine maintenance and repairs fast and efficient.

- Our Labeling and Coding brands proudly offer the PMMI Certified Trainer Program. This recognized designation ensures that the highest standards of quality training are being met and unparalleled value is given to the customer.

Contact an EPI Account Manager

Ready to improve your production output and operational efficiency? Contact an EPI account manager today to learn how our labeling automation solutions will increase your throughput and improve your bottom line.